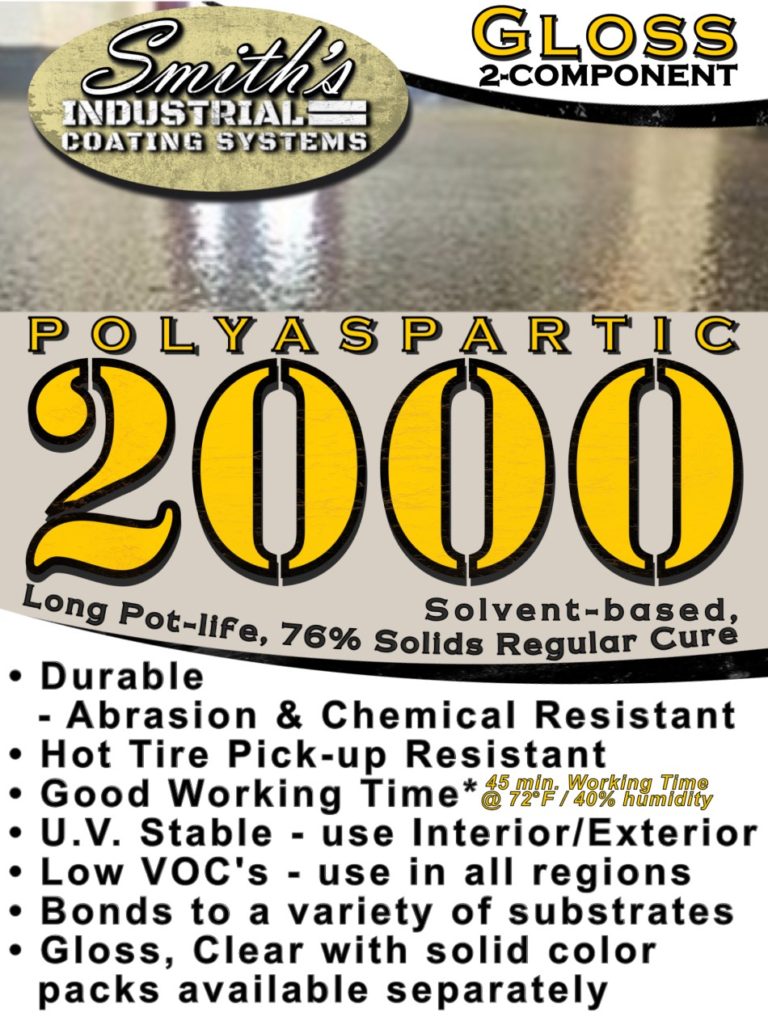

Smith's Polyaspartic 2000 - 76% Solids, 45 minute working time

Smith's Polyaspartic 2000 - 76% Solids, 45 minute working time

Couldn't load pickup availability

Smith’s Polyaspartic 2000 is a 2-Component, High-Performance, 76% Solids Aliphatic Polyaspartic coating with a gloss finish which yields a Resilient, U.V. Stable and Abrasion Resistant film with very good splash and chemical spill properties for application to a variety of substrates including, but not limited to concrete, wood and metal.

Smith’s Polyaspartic 2000 was developed for ease of use with a 1A to 1B mix ratio plus a longer working time versus most competitors Polyaspartic or Polyaspartic-Polyurea products.

Smith’s Polyaspartic 2000 is an excellent coating system for Vinyl Chip, Color Quartz, Smith’s Metallic & Luster, fast return-to-service broadcast shop floors and pigmented applications for Residential, Retail, Commercial or Industrial environments which demand color stability, faster return-to-service and durability.

Smith’s A/O 325 Low Sheen additive is available separately to achieve a low sheen finish as a topcoat with Smith’s Polyaspartic 2000 roller applied at 500 sq.ft. per gallon. For additional traction, use a slip resistant additive such as Smith’s Resin Sand.

HIGHLIGHTS:

- Fast Return-to-service

- Easy to Clean

- Superior Performance

- Clear with color options:

- Smith’s ISC Solid Color Packs sold separately

- Metallic & Luster Mica Color Blends sold separately

- Gloss finish

- Accepts Smith’s A/O 325 Low Sheen Additive as a low sheen topcoat (Roller apply at 500 to 600 sq.ft. per mixed gallon)

- U.V. Light Resistant

- Resistant to stains & chemicals

- Resistant to hot tire pickup

- For Interior & Exterior Use

- Low VOC’s – Less than 2 g/L

- Meets Source Specific Standards Rule 1113 established by AQMD in California

- Meets FDA & USDA standards for flooring

Share