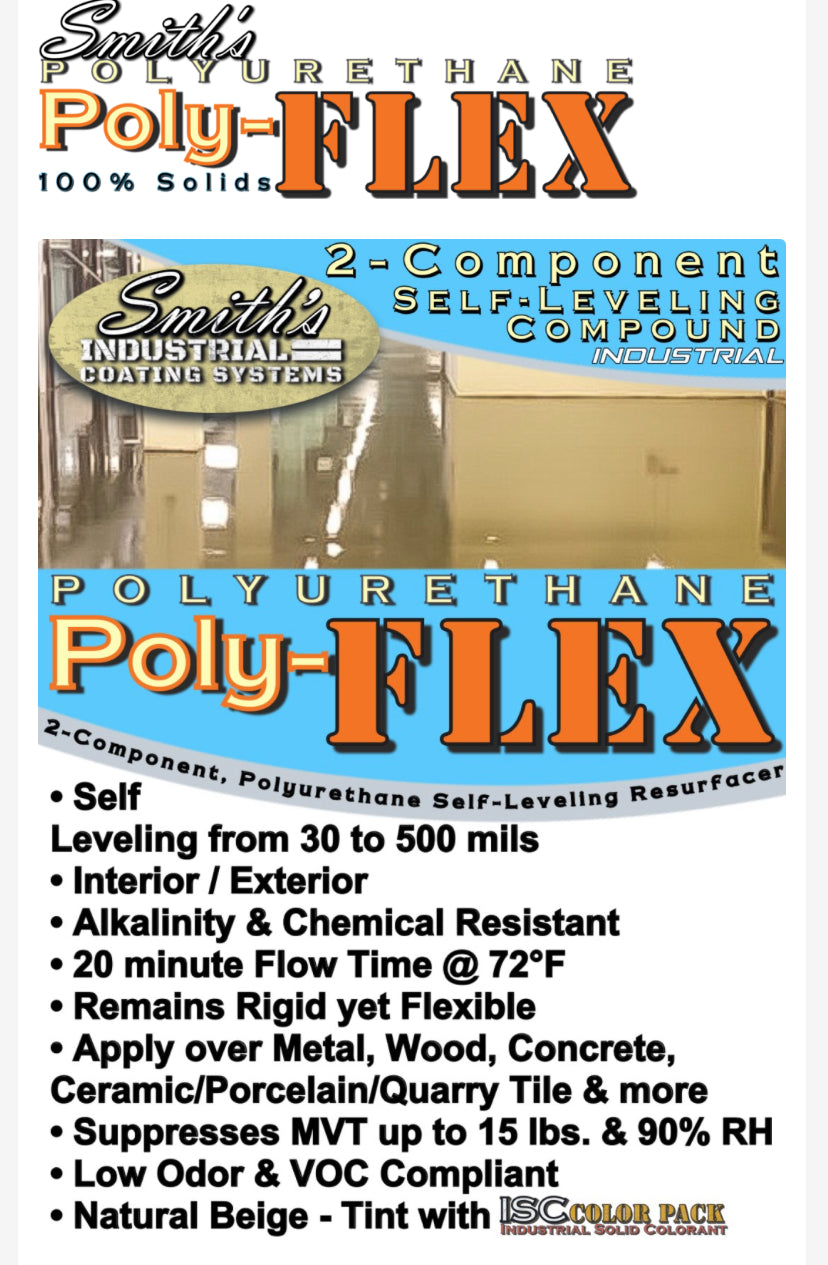

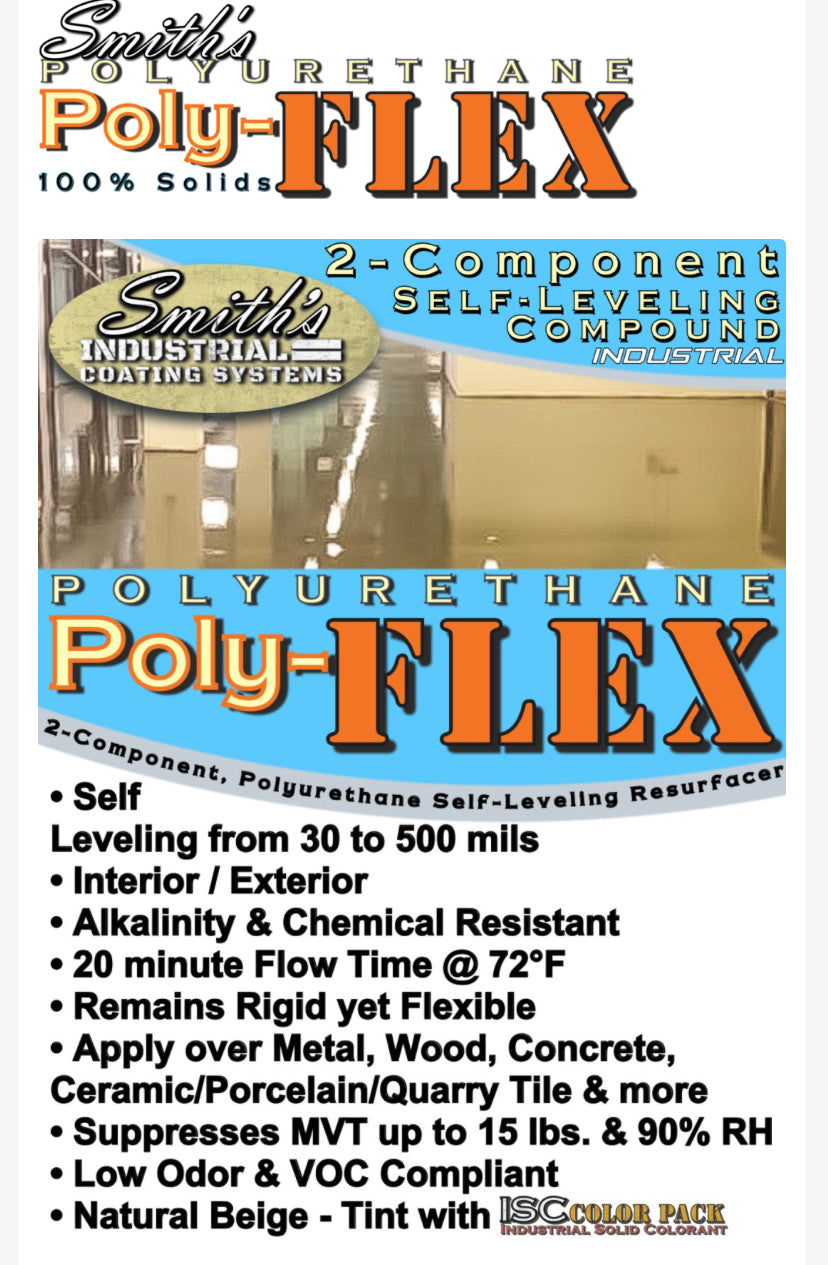

Smith’s Poly-Flex DIRECT SHIP ONLY

Smith’s Poly-Flex DIRECT SHIP ONLY

Couldn't load pickup availability

Smith’s Poly-FLEX is a Heavy-Duty, 2-Component, Moisture Tolerant, Semi-Rigid Polyurethane Flowable Resurfacing Compound with good elongation characteristics to aid in suppressing minor cracks from telegraphing through yet rigid enough for traditional applications. Walkable in roughly 2 ½ hours and accepts subsequent layers/systems in as little as 4 hours. Applies from a minimum of 30 mils up to 5 inches in a single lift. Tenaciously bonds to a variety of substrates.

Smith’s Poly-FLEX is freeze/thaw stable allowing for use as a base for interior and exterior resinous or cement overlay (with a sand broadcast) systems. Also suitable over radiant floor heating systems. Smith’s Poly-FLEX suppresses up to 15 lbs. (ASTM F-1869) or 90% RH (ASTM F-2170) of osmotic moisture vapor transmission with up to 14 pH on concrete slabs when properly mechanically prepared.

RECOMMENDED USES:

- Base layer for:

- Double Broadcast Color Quartz

- CPR Cementitious Polyurethane

- Vinyl Chip

- Epoxy Slurry

- Epoxy Mortar

- Trowel Color quartz epoxy mortar

- Shop Floor systems

- Smith’s 4in1 Overlay

- Metallic floor coating systems and more

APPROVED SUBSTRATES:

- Ceramic, Porcelain, Stone & Quarry Tiles

- Well Bonded, mechanically prepared existing coatings (i.e. Epoxy, Cementitious Urethane, Methyl Methacrylate, Polyaspartic & Polyurethane)

- Concrete & Polymer Modified Overlays

- Metal Floors (Stainless Steel, Iron, Steel, Copper, Treated Aluminum*)

- Terrazzo

- Wood Subfloors (underlayment grade plywood or OSB; requires use of Smith’s Epoxy FW38 primer)

HIGHLIGHTS:

- Self-Leveling (when applied greater than 30 mils)

- 100% Solids – Contains no Solvents or Water

- Chemical Resistant

- Alkalinity Resistant

- Tenacious Bond

- Low Odor & Zero VOC’s

- Flexible

- Resists Aging & Elasticity Fatigue

- Suppresses Minor Cracks from Telegraphing to surface

- Suitable for use over In-floor Radiant Heat systems

- Accepts a variety of Floor Coating & Cementitious Overlays within in 4 hours at 72°F & 50% Humidity

- Withstands up to 15 lbs. (per ASTM F1869) and up to 90% In-situ Relative Humidity (per ASTM F2170)

Share